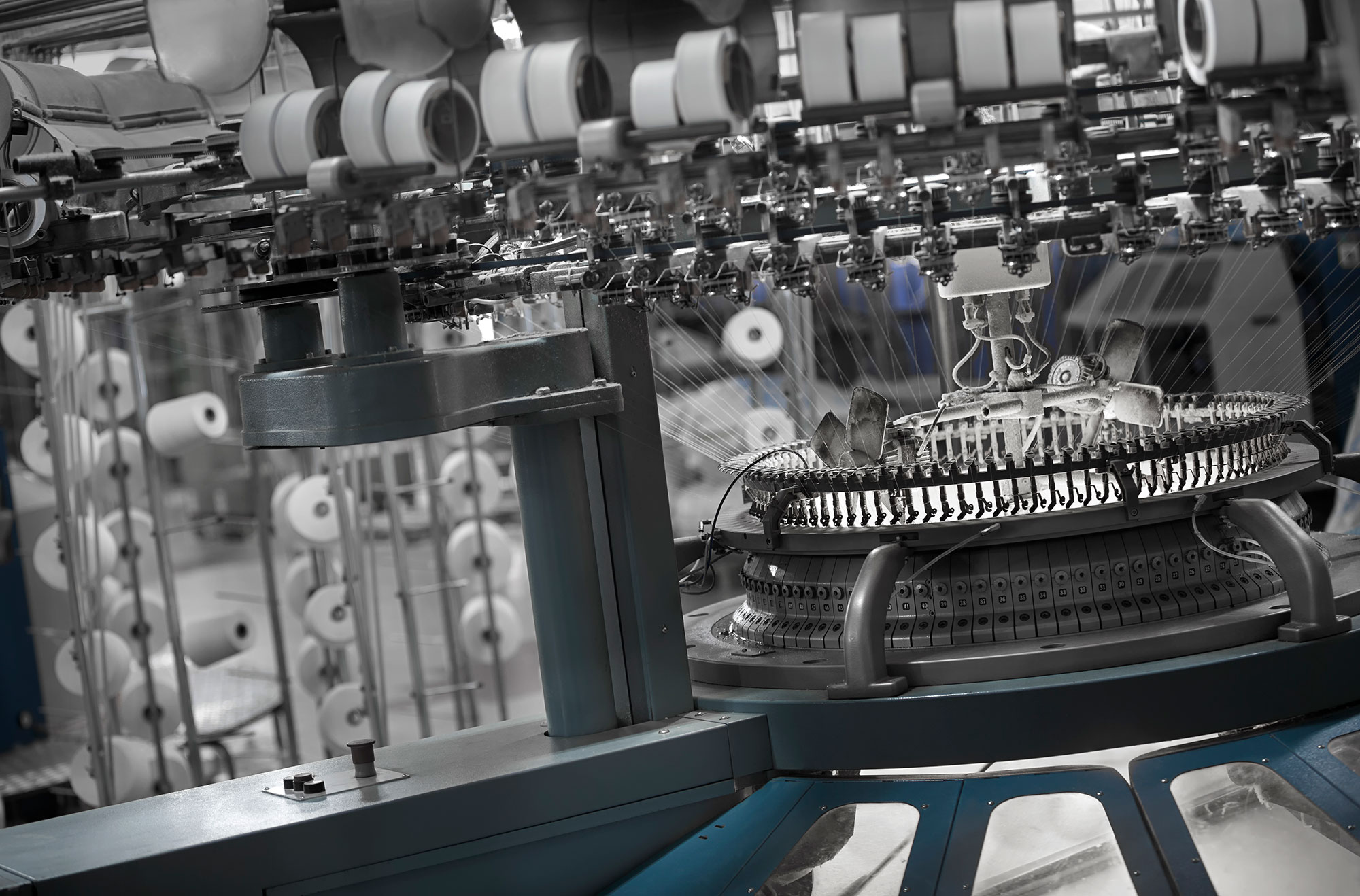

The idea started with a broad brush stroke: Create the world’s best hoodie. After The S Group conducted an extensive study of over 50 brands, the decision was made that American Giant needed a fabrication that emulated the vintage collegiate fleece hoodies from the 50’s and 60’s. This classic heavy weight and durable fabrication was developed and incorporated into their signature hoody that has since expanded into an entire collection that is designed and developed in the USA.